Ultimate Grip, Unmatched Mobility

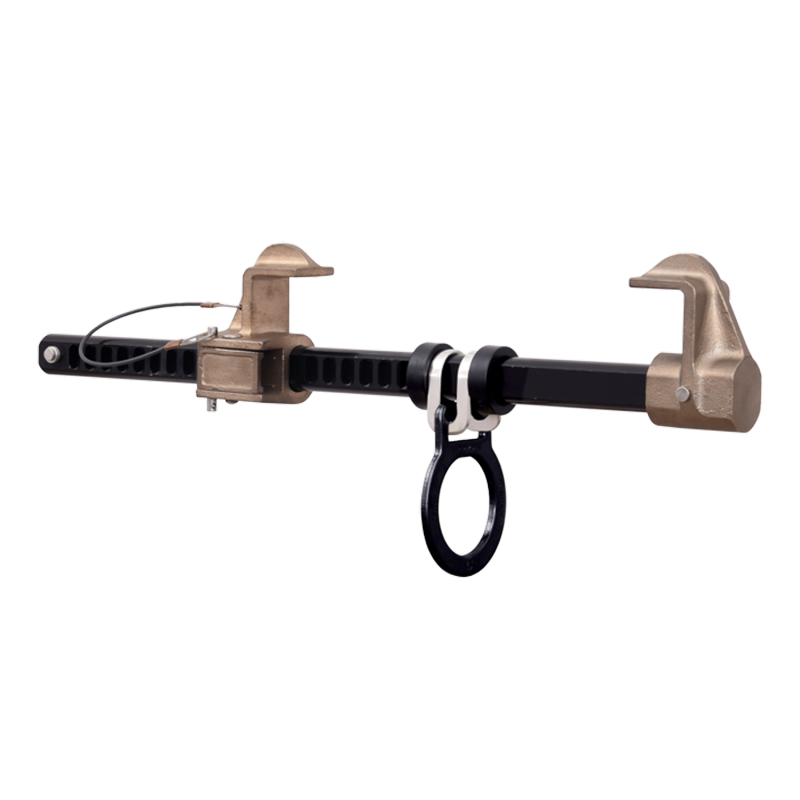

The KSTRONG AFA930401 Beam Clamp Anchor—Your Absolute Trust at Height.

- A professional-grade, portable fall arrest anchor that clamps quickly onto I-beams and H-beams.

- Designed for construction, maintenance, and industrial professionals who work at height around structural steel.

- Tool-free installation, an ultra-lightweight design (1.87kg), and an exceptionally wide adjustment range (90-340mm) that fits most industrial beams.

Value & Benefits

- Boosts Work Efficiency: The innovative quick-adjust clamp design allows for installation and removal in seconds without any tools, significantly cutting down on prep time and getting your crew to work faster.

- Ensures Worker Safety: Rigorously tested to a minimum breaking strength of 23kN, far exceeding single-user requirements. A secure locking mechanism guarantees absolute stability in the event of a fall, providing a solid foundation for protecting your most valuable assets—your people.

- Reduces Equipment Costs: Its high portability and reusability make it a high-ROI asset. A single anchor adapts to a wide array of beam sizes, reducing the budget needed for multiple, site-specific anchor models.

- Delivers Ultimate Flexibility: The expansive adjustment range and lightweight build make it suitable for diverse environments, from construction sites to complex industrial plants, offering your team a truly universal and reliable fall protection solution.

Performance

- Maximum Rated Load: 140 kg (310 lbs) for one person

- Minimum Breaking Strength (MBS): 23 kN (5,170 lbf)

- Static Strength: Withstands a 12 kN (2,697 lbf) load for 3 minutes without failure

- Dynamic Performance: Successfully arrested a 100 kg (220 lbs) rigid mass drop, with the anchor remaining stable

- Applicable Load Direction: Maximum angle of 45° from vertical

Specifications

- Compatible Beam Flange Width: 90 mm - 340 mm (3.54" - 13.38")

- Product Weight: 1.872 kg ± 0.020 kg (4.13 lbs ± 0.044 lbs)

- Product Dimensions (L x H): 467.0 mm x 89.0 mm (18.38" x 3.50")

- Materials of Construction:

- Locking Beam: High-Strength Aluminum Alloy

- Main Housing & Cover: High-Strength Aluminum Alloy

- D-Ring: Alloy Steel

- Clamping Jaws Flange: Brass

- Finish: Anodized

Certifications

- European Standard (CE): EN 795:2012 Type B

- American Standard (ANSI): ANSI Z359.18-2017 Type A

- Australia/New Zealand Standard (AS/NZS): AS/NZS 5532:2013

- EU Notified Body: CE 0598 (SGS Fimko Oy)

- ATEX Certification: EN 80079-36:2016, EN 80079-37:2016 (Suitable for use in potentially explosive atmospheres)

Maintenance

- Pre-Use Check: A visual inspection must be conducted before each use, checking for any deformation, corrosion, cracks, or missing parts, and ensuring the locking mechanism functions correctly.

- Periodic Examination: A formal, documented inspection must be performed by a competent person at least every 12 months. More frequent inspections are required in corrosive or high-use environments.

- Cleaning: Clean with a cotton cloth or soft brush. For intensive cleaning, use a neutral detergent with water no hotter than 60°C. Allow to air dry naturally, away from direct heat.

- Storage: Store in a well-ventilated area away from extreme temperatures, chemicals, UV exposure, and direct sunlight.